Description of production line

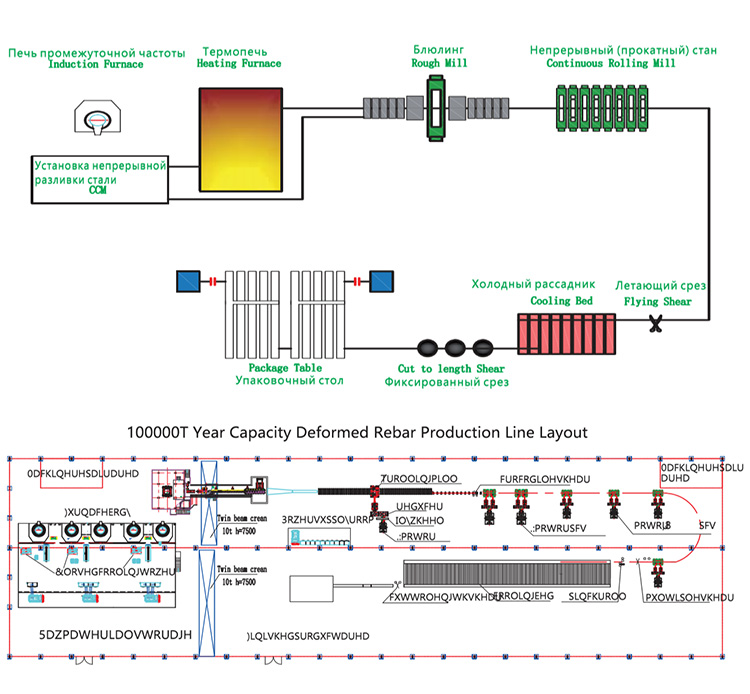

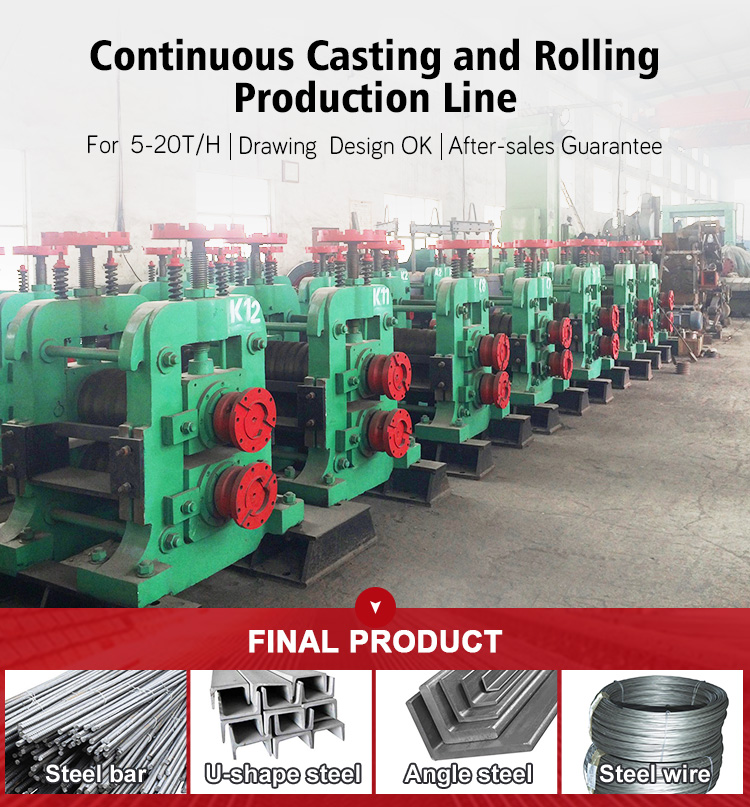

Continuous casting and rolling Production Line including Induction Furnace, CCM Machine, Heating Furnace, Rough Mill, Continuous Rolling Mill, Flying Shear, Cooling Bed, Cut To Length Shear, Packing Table etc.Features of Continuous rolling mill

* Save energy consumption by using continuous casting blanks heat energy. * Improve the metal forming and save the metal consumption. * Simplify production process , reduce plant area and transportation cost, save infrastructure investment and production costs. * Greatly shorten the production cycle * Improve the quality of the products * The raw material is steel scrap or billet (40-120mm). *The production capacity is suitable for 5~20t/h, and the diameter of the steel bar of the finishing product: 6.5-32mmTechnical specifications table

| Annual capacity(T) | Capacity(TPH) | Working hour/year | FurnaceCapacity(T) | Continuous casting | Continuous Rolling | Area(m) | Power(MW) | Remarks | |||

| Model | Section(mm) | Rough | intermediate | Finishing | |||||||

| 7000 | 3 | 2400 | N/A | R2.5 | 40x40 | FF250x2 | Ff220x2 | FF220x2 | 40x10 | 0.6 | 8~32mm |

| 10000 | 4 | 2400 | 1.5Tx3 | R2.5 | 50x50 | FF280x3 | FF250x2 | Ff220x2 | 80x15 | 4.5 | 8~32mm |

| 12000 | 5 | 2400 | 2Tx3 | R2.5 | 60x60 | FF280x3 | FF250x2 | FF250x2 | 120x20 | 5 | 8~32mm |

| 20000 | 8 | 2400 | 3Tx3 | R2.5 | 70x70 | FF350x3 | FF280x2 | FF250x2 | 120x20 | 8.5 | 8~32mm |

| 40000 | 10 | 3600 | 3Tx4 | R3.5 | 90x90 | FF380x3 | FF300x2 | FF280x2 | 150x20 | 9.5 | 8~32mm |

| 50000 | 15 | 3600 | 5Tx3 | R5.5 | 120x120 | FF450x3 | FF350x2 | FF280x2 | 180x20 | 10 | 8~32mm |

| 100000 | 16 | 60000 | 5Tx4 | R6x2 | 120x120 | FF450x3 | FF400x2 | FF280x2 | 120x32 | 15 | 6.5~32mm |

| 200000 | 35 | 6000 | 10Tx4 | R6x2 | 150x150 | FF550x3 | FF450x2 | FF280x2 | 180x32 | 26 | 6~32mm |

| Specifications for reference only , could be adjust according to customer’s site area and requirement.Working day per year according to 300 days. | |||||||||||

Our Service

* Provide convenient combined overall solution including factory steel structure building, overhead cranes for steel mills, Continuous Casting and Rolling Production Line and related equipment. * Provide turnkey project including design, manufacturing, transportation, installation, commissioning and testing service. * Provide factory building design, overall equipment layout, rolling mill process design, electrical circuit layout and other services. * Provide guaranteed after-sale service.Working principle of continuous rolling mill

The continuous rolling mill is an advanced process which can reduces the working load and improve the steel rolling speed. Its main feature is that the rolled steel metal is in a numbers of rolling mills at the same time, and are are rolled in the same direction, and finally form to a certain sectional shape such as steel rebar, wire rod, channel steel, section bar, flat bars, steel plates and other products.images